Precision Steel Parts Made in China for Industry/Equipment by OEM Manufacturer

Product Details

| Item | Steel Parts for Industry Equipment |

| Surface Preparation | Sand Blasting, Plating, Galvanized, Spray-Paint, Passivating, Polishing, Electrophoresis, Machining, etc. |

| Surface Treatment | Shot blasting/Polishing/Painting/Powder coating/Anodizing/Zinc plating/Nickel plating/blacking, etc. |

| Surface Roughness | Ra0.05∼Ra50, depends on Customer’s Requirements |

| Heat Treatment | Normalizing, Annealing, Quenching, Tempering, etc. |

| Process | Mold Making, Casting, Machining, Surface treatment, Inspection, Packing, Loading |

| Casting tolerance | CT5-CT8 |

| Casting blank size | 2mm-1500mm or according to customer's requirement |

| Casting blank weight | 0.01kg-3000kg |

| Coating | Electrophoresis Coating |

| Machining | Lathing/Milling/Turning/Boring/Drillig/Tapping/Grinding, etc |

| Machining tolerance | 0.01mm |

| Design software/ formats | 3D, Auto CAD (IGS,DXF,DXF,DWG,STP, STEP,STL,X-T)/Soild Works/CAXA/Rhino/CATIA/SIMIO/ALIAS/ARENA/Unigraphics, etc |

| Certification | ISO9001:2015, CE, SGS, RoHS, IATF16949 |

| Inspection Equipment | Test equipment: Spectrum Analyzer, Hexagon CMM, Hardness test equipment, Tension test machine, E-coating testing equipments, Metalloscope. |

| Dimension Inspection | Coordinate Measuring Machine (CMM), Calipers, Height Gauge, Micrometer Calipers, Inside Caliper Gauge, Angle and R Gauge, customized gauge, etc. |

| Application | Agriculture Equipment, Mining Equipment, Marine Equipment, Petroleum Equipment, Engineering Equipment, Shipbuilding Equipment, Power Equipment, etc. |

| Package | Bubble plastic bag/polybag/pallet/wooden case, etc. |

| Trademark | OEM |

| Origin | China |

| Loading Port | Qingdao Port |

| Annual Supply | 1000000 Pieces |

| Sample | Available |

| Sample production cycle | 30-45 Working days. |

| OEM/ODM service | Available |

Product Description

Custom Precision CNC Machinery Part Air/water connection Syringe attachment Aluminum CNC Machining Valve cap Toy Glock Parts

1. Process: CNC machining

2. Machining Parts

3. Smooth surface

4. ISO certified factory

5. Accept small OEM trial order

OEM/ODM service

1. Over 40 years foundry experience

2. High quality control, Competitive price, Instant delivery

3. Small quantity for trial order is acceptable

4. Sample and drawing available

5. OEM/ODM available

6. One-stop service

| 1. Aluminum/Brass/ stainless steel Precision Product | 2. Extrusion/ Profile |

| 3. Hardware | 4. Injection molding |

| 5. Aluminum Frame | 6. Furniture Part |

| 7. Aluminum Office and Living Product | 8. CNC Precision Milling Part |

| 9. CNC Precision Turning Part | 10. Punch& Stamping& Stretching& Riveting& Assembly |

| 11. Die Casting& Welding& Forging& Bending Part | 12. Medical Aluminum Part |

| 13. Aluminum Pipe | 14. Large Cross-section/ High Challenge Heat Sink |

| 15. Mechanical Industrial product/ Auto Part | 16. LED Aluminum Accessory |

| 17. Mold Design and Manufacture | 18. Surface treatment |

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316 etc.

2. Carbon Steel: AISI 1045, 9SMnPb28 etc

3. Brass:C36000 (C26800), C37700 (HPb59), C38500(HPb58), C27200(CuZn37), C28000(CuZn40) etc.

4. Bronze: C51000, C52100, C54400, etc.

5. Iron: grey iron and ductile iron

6. Aluminum: 6061, 6063,7075,5052 etc.

Application fields

The castings produced by us are widely used in various industries, such as automobile, car, heavy truck, light truck, commercial vehicle , forklift, construction machine/ machinery/ truck/ vehicle/ equipment, farm/ agriculture vehicle/ machine/ machinery/ truck/ equipment, mining machine/ machinery/ vehicle/ truck/ equipment, marine hardware, train, railway, railroad, petroleum machine/ machinery/ equipment/ device/ facility/ installation, engineering machine/ machinery/ truck/ vehicle/ equipment/ device/ facility/ installation, shipbuilding machine/ machinery/ equipment/ device/ facility/ installation, power machine/ machinery/ equipment/ device/ facility/ installation, and other mechanical indusrty. We can produce all kinds of castings according to customer's drawings and customer's requirements, including but not limited to the following:

Steel accessory, precision steel accessory, stainless steel accessory, carbon steel accessory, alloy steel accessory, metal accessory, metal processing, metal stamping, metal punching, metal molding, stamping accessory, punching accessory, turning accessory, molding accessory, machining, cnc machining, machining accessory, cnc machining accessory, cnc accessory, machining foundry, casting foundry, steel stamping, steel punching, steel turning, steel molding, professional casting, precision casting, precision stamping, precision punching, precision turning, precision molding, casting manufacturer, casting manufactory, custom casting, precision machining, precision casting steel, sand casting, die casting, lost wax casting, investment casting, gravity casting, nonstandard accessory, auto accessory, spare accessory, auto spare accessory, car spare accessory, truck spare accessory, lorry spare accessory, automotive spare accessory, automobile spare accessory, automotive accessory, automobile accessory, car accessory, truck accessory, lorry accessory, heavy truck accessory, heavy-duty truck accessory, transport truck accessory, heavy transport vehicle accessory, vehicle accessory, forklift accessory, farm vehicle accessory, farm truck accessory, farm machinery accessory, farm machine accessory, agricultural vehicle accessory, agriculture vehicle accessory, agricultural truck accessory, agriculture truck accessory, agricultural machinery accessory, agriculture machinery accessory, agricultural machine accessory, agriculture machine accessory, combine harvester accessory, tractor accessory, trailer accessory, mining equipment accessory, mining machinery accessory, mining machine accessory, mining truck accessory, mining vehicle accessory, industrial accessory, industry accessory, equipment accessory, machinery accessory, machine accessory, mechanical accessory, device accessory, facility accessory, engine accessory, motor accessory, pump accessory, pump body, pump shell, pump housing, pump casing, pump cover, water pump, impeller, pump impeller, hydraulic pump accessory, pump spare accessory, water pump accessory, hydraulic spare accessory, stainless steel pump, centrifugal pump, slurry pump, sewage pump, electric pump, submersible pump, high pressure pump, chemical pump, pressure pump, water pump set, self-priming pump, garden pump, deep well pump, oil pump, fountain pump, pond pump, mud pump, single suction, fuel pump, diesel, water pump, vacuum pump, auto pump, car pump, automotive pump, automobile pump, vehicle pump, truck pump, lorry pump, valve accessory, valve body, valve shell, valve casing, valve housing, gate valve, ball valve, connector, solenoid valve, pipe fittings, control valve, floating ball valve, pneumatic valve, industrial valve, gas valve, flange gate valve, directional valve, hydraulic control valve, butterfly valve, gearbox, gearbox accessory, gearbox body, gearbox shell, gearbox casing, gearbox housing, oil cylinder, cast iron, cast steel, cast iron accessory, cast steel accessory, casting accessory, iron casting, steel casting, metal casting, cast metal accessory, sand cast accessory, sand casting accessory, cast machine accessory, cast machinery accessory, machine spare accessory, hardware, coupling, marine hardware, precision accessory, high performance accessory, high quality accessory, truck bracket, lorry bracket, engine bracket , motor bracket, steering gear bracket, leaf spring bracket, balanced suspension, suspension system, suspension arm, steering knuckle, vehicle bracket, bumper bracket, exhaust pipe, exhaust pipe manifold, diesel engine, etc.

How to order

* You send us drawing or sample

* We carry through project assessment

* We feedback you a design

* You approve the design

* We make the sample and send it to you for your approval

* You check the sample, if all is OK, then place an order and make a 30% deposit

* We set to arrange the mass production

Processing Method: cnc machining, turning, milling, drilling, grinding, broaching, welding and assembly.

FAQ

Q: Where can I get product&price information?

Send us an inquiry on the page or e-mail, we will contact you after upon receipt of your mail.

Q: How soon can I get samples and how much the fee?

Depending on your specific project, it usually takes 10 to 20 days. the fee depends on your parts drawing, and the fee will be returned to your bulk order.

Q: How to enjoy the OEM services?

Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you.

Q Can you make machining parts based on our samples?

Yes, we can make measurements based on your samples to make drawings for machining parts making.

Q: Is it possible to know how are my products going on without visiting your company?

We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Q: Will my drawing safe after you get it?

Yes, we can sign the NDA before got your drawing.

Q:Why choose your company?

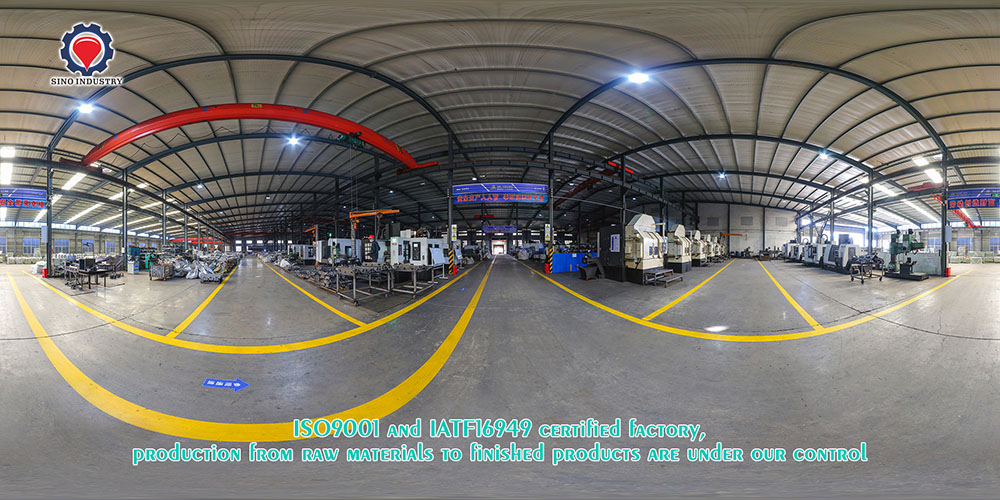

We are a leading manufacturer in the casting/forging/machining industry. We have superior production equipment, strict and effective quality assurance system, excellent and perfect detection means, rich technical force. More than 40 years experience in casting/machining industry, with 60 experienced technical engineers and 800 skilled workers. We are a source manufacturer, and we have a complete production line, all production links from raw materials to finished products are under our control. Our products have a considerable price advantage relative to intermediary traders.

Q:Do you provide OEM Service?

Yes, as a “ISO9001” and “IATF16949” certified factory, we provide real one-stop service and optimal solution, as well as professional OEM/ODM casting/machining service for customers. Actually, our factory is the Chinese automobile manufacturer giants FAW/ FOTON/ SINOTRUK/ SANY/ HOWO/ SHACMAN designated supplier for customized casting&machining parts.

Q:Do you provide customized machining products?

Yes. Customers to provide drawings or samples along with detailed specifications, and we will process accordingly.

Q:What is your payment term?

L/C, T/T, Paypal, etc.